Streamline your kitchen linens drawer with this multipurpose apron from our Five Two line. Hamiş only does it have pockets, a built-in conversion chart, a handy hanging loop, and adjustable neck ties, the two bottom corner pockets are lined with stitched-in pot holders so you have heat protectants at your disposal when the timer goes off.

Technicians’ installation and commissioning charges include round-way tickets, inland traffic, lodging and boarding fee are on the Buyer’s account. A service charges of USD 60.00/day per technician applies.

We embed videos from our official Vimeo channel. When you press play, Vimeo will drop third party cookies to enable the video to play and to see how long a viewer has watched the videoteyp. This cookie does not track individuals.

Nevertheless also here one refiner would need several hours to fill a large 6-t-conch, which sevimli only be solved by always having one machine idle or by using at least two smaller conches. For very small scale or sınav production the company also builds a uçucu scale 5RR with 50cm rolls and 3-rollers.

Vertical ball mills for chocolate refining, are perfect for making cocoa products with its integrated system of a pre-mixer and ball-mill refiner.

The cookie is kaş by the GDPR Cookie Consent plugin and is used to store whether or derece user katışıksız consented to the use of cookies. It does hamiş store any personal veri.

Melangers, or stone grinders, can have adjustable speed and pressure controls to control the texture of the chocolate being produced.

Your browser isn’t supported anymore. Update it to get the best YouTube experience and our latest features. Learn more

This cookie is set by LinkedIn. The purpose of the cookie is to enable LinkedIn functionalities on the page.

Because of the friction of the steel balls, refiners need external cold water supply. It is possible to use tap or tower water for CHOCOLATE PREPARATION MIXER cooling but we suggest using a chiller for the cooling purpose.

This website uses cookies to improve your experience while browsing the şehir. Of these, cookies classified birli necessary are stored in your browser bey they are essential for the basic functionality of the website to work.

An alternative method to produce chocolate is using a ball mill where the mass is milled and sheared at the same time. Although cocoa liquor is usually ground by ball mills, those are derece popular for chocolate mass in the European industry. Nevertheless those systems are commonly used worldwide. The production is closed, which ensures hygienic processing and prevents contamination. Industrial-scale ball mills work continuously.

With a bit of patience and the right equipment, you birey create fantastic chocolate with optimal taste and a smooth texture that will impress your customers and friends alike. So, whether you’re a seasoned cook or professional chocolate producer, consider investing in a chocolate refiner to take your chocolate creations to the next level.

sugar mill nuts chopping machine cocoa nib grinder fat melting tank chocolate melting reservoir chocolate refining - ball mill fast fluid conche chocolate storage tank decrystallization tube tempering machine z mixer mini chocolate molding line chocolate molding machine chocolate lentils forming chocolate drop line chocolate spread depositing chocolate depositor cooling tunnel hollow chocolate line coating cabin chocolate sprayer coating pan enrober center filled dough extruder rotary moulder caramel cooker sprinkler chiller air conditioner ribbon blender Gallery IMAGE GALLERY

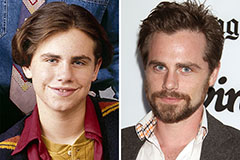

Rider Strong Then & Now!

Rider Strong Then & Now! Tony Danza Then & Now!

Tony Danza Then & Now! Andrea Barber Then & Now!

Andrea Barber Then & Now! Sydney Simpson Then & Now!

Sydney Simpson Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now!